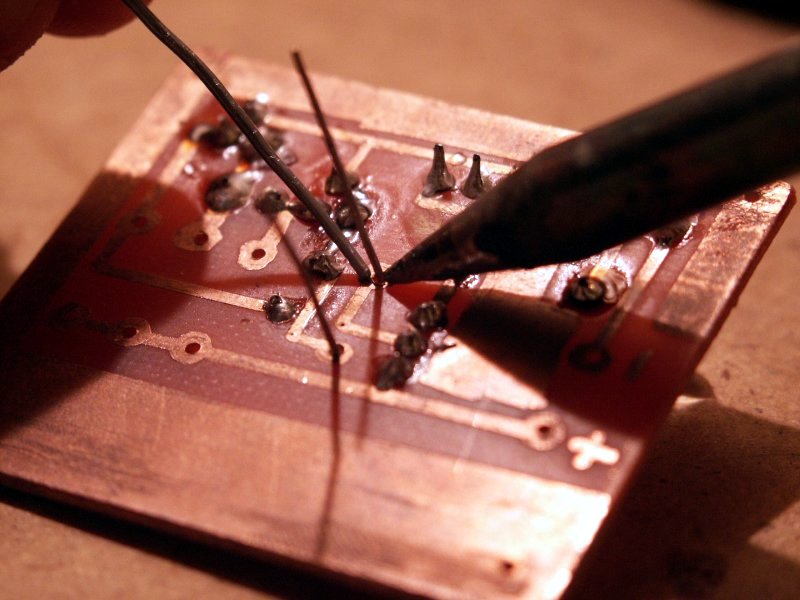

Soldering Iron Tips

Soldering irons use different kinds of tips for various purposes. Some are easier than others to use, some are more precise, so make sure you’re choosing a tip that suits your skill level and project requirements. Tips with a larger surface area allow more heat to transfer, which is useful when your solder is composed of a higher percentage of harder metals. It also speeds the process along because the heat transfer is more efficient. On the other hand, finer tips offer more precision. This is especially important for work that requires more finesse, or when you’re working with especially small pieces (such as on a circuit board). There is a huge variety of tips out there, but we’ll take a look at the most common categories

Soldering tips are generally divided into “series.” We’re going to cover B, D, C, I and K series tips.

What Kind of Irons Should Be Used with These Tips?

not all soldering irons and stations can accept interchangable tips. If you want to know what models can be used with this tip, check out our guide to the best soldering stations.

K Series

K Series tips have a slanted knife shape, and are sometimes referred to as a chisel tip. They’re easy to maneuver, and useful for a variety of jobs. This makes the K series tips great for beginners. They’re the tip you’ll find in any good solder tip collection. The one downside to a chisel tip is that it’s not ideal for precision work. Chisel tips are great for wires, through-hole components, large surface-mount components as well as desoldering.

C Series

C series tips look a bit like they were ground down on one side. They are also referred to as bevel tips. These are slightly different than “hoof” tips (or CM series), which have a concave surface impression that allows for the distribution of excess solder. C series tips are ideal for drag soldering, a strategy used when soldering circuit boards.

D Series

D series tips have a somewhat chisel shape, but are more rounded than the K series chisels. They are often referred to as conical tips. They come in a variety of sizes are best thought of as an all purpose tip. They have good maneuverability like the K series, but have a larger surface area, which has its pros and cons. The upside is that there is more heat transfer, so they’re better for quick jobs. The downside is that there is less precision, so they’re not ideal for jobs involving particularly small pieces.

B Series

B series tips are what you’d imagine a standard soldering tip to look like. It is shaped basically like a pencil tip. It’s another great general purpose tip because it has lots of different applications. The rounded tip allows you to solder from any angle, which is especially useful for jobs that require a bit of precision. They’re a good balance between effective heat distribution and accuracy, and are ideal for small surface-mount components.

I Series

I series tips are narrow and pointy. They require a bit more skill and familiarity with soldering to be used properly. The offer the most precision, but also require a bit more patience as the lower surface area means it take more time and effort to properly heat the source. These tips are especially useful in needle-point precision work, but are a bad choice for larger components.

Beyond these categories, there are endless examples of specialized tips for specific jobs. Unless you’re an experienced solderer, you likely won’t use many specialized tips. The most important thing when buying a tip is to make sure it’s compatible with your soldering iron. It’s not always necessary to buy within the same brand (which can be costly), but you’ll definitely want to check sizing and compatibility before committing to any one tip.